- Tel: 0086-13507449007

- E-mail: sales@marya.com.cn

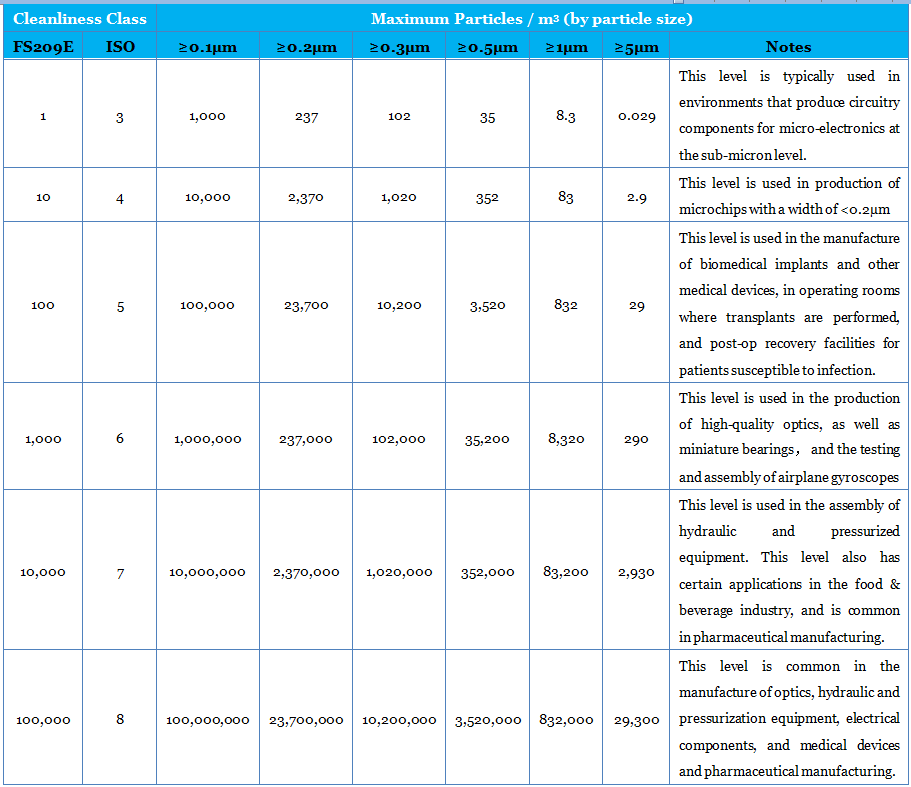

1. Our clean room project cleanliness level is high, meeting the requirements of GMP, FDA, WHO and other pharmaceutical standard;

2. Able to realize BMS automatic control;

3. Modular design, fast installation;

4. Clean room project construction material are CE certified;

5. High degree of safety, equipped with safety doors and fire dampers;

6. From A-Z, one-stop service from design to construction verification;

7. Can accurately control the temperature, humidity, pressure difference, the number of dust particles and planktonic bacteria;

8. The brand of HVAC can be specified by customer;

9. Able to send workers abroad for installation;

10. We have a strong design team, able to design according to customers' different needs.

| Cleanroom Project Scope(from structure, HVAC,electric to auto-control) | 1. Cleanroom Structure: Wall Panel, Ceiling Panel, Windows, Doors, Fittings, Flooring | ||

| 2. HVAC: AHU, Chiller, dehumidifier, Ducting, Piping, etc. | |||

| 3. Electric: Lighting, Switch, Cables, Wires, Power Distribution Cabinet, etc | |||

| 4. Auto-control: PLC Controller, Sensors for Humidity and Temperature, Control Panel | |||

| 5. Process Piping System: Gas, Water Pipeline | |||

| Equipment | Air shower, Cargo shower, Mist shower, Dynamic pass box, Static pass box, Sampling booth, Weighing booth, Dispensing booth, Medicine stability test chamber, isolator, VHP sterilizer, Biological safety chamber, FFU, LAF, etc. | ||

| Temperature | 21-27℃ (or as per required) | ||

| Humidity | 30-60℃ (or as per required) | ||

| Application | Pharmaceutical factory, hospital, medical device workshop, electronics workshop, food factory, cosmetics factory, etc. | ||

| Qualification Documents | DQ, IQ, OQ, PQ | ||

| Full Service | FAT and SAT Service, Professional Consultation, Training, User-friendly English Software, 24 hours technical support | ||